🗸 Competitive Pricing 🗸 Quality Service 🗸 Extensive Stock 🗸 Experienced Staff

Price

PriceA Guide to Straight Router Cutters

A Guide to Straight Router Cutters

Straight router cutters are primarily used for cutting grooves, slots, recesses and dados, but straight or parallel flute cutters can also be used for mortising, edge trimming and, in conjunction with guide bearings and bushes, for template work. They are the most basic cutters and vary enormously in size from tiny 1.5mm diameter ones for delicate work up to massive 50mm diameter versions. Cutter lengths vary from 5mm to 65 mm so the range is enormous.

Single flute straight cutters

Single flute straight cutters are used for applications where fast cutting is of more concern than the standard of the finish. As they only have one cutting flute they allow waste material to clear easily and have good plunge cutting characteristics, making them ideal for rough cutting operations and for cutting out prior to edge trimming or profiling. Allows faster feed rates to be maintained, but generally to the detriment of the finished cut edge.

Two flute straight cutters

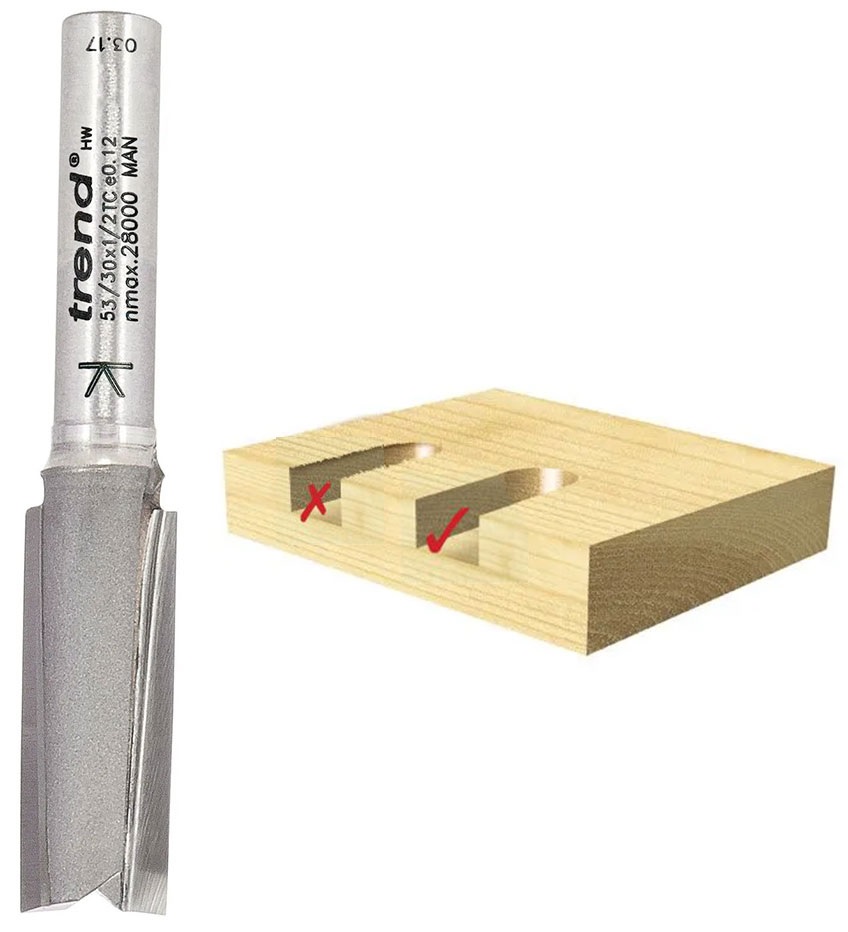

Two flute straight cutters are used for most routing operations, including edge trimming, grooving and rebating. Although they produce a superior surface finish to single flute cutters, waste clearance is far slower necessitating a slower feed speed. Cutters without ‘bottom cut’ should only be fed horizontally into the material, from the edge of the work or from a pre-drilled pilot hole.

Both 6.3mm and 12.7mm diameter straight cutters are suitable for grooving and rebating. A 1/4 inch (6.35mm) cutter can be plunged in centrally away from the board edge.

Tongue and groove joints. Use a straight cutter to rout a square tongue on the edge of a board. Cut a matching groove down the centre of the other component, using a wooden strip clamped to both sides to provide a wide flush surface to support the base of the router.

Rebated and grooved joints. Lap joints, barefaced housings and halving joints are all variations on a basic theme. By clamping several components together flat on a bench you can cut any one of these joints using a straight cutter in a router run against a guide batten.

Always resist the temptation to rout grooves and joints in one pass of the router, so take several shallow cuts.

This will ensure a better finish is obtained and it will reduce the load on the router. Mounting a waste piece at the end of the components clamped ready for machining will ensure the end panel does not split out (the cut is carried through into the waste piece).

Down-cut shear flute cutters

Down-cut shear flute cutters have a slicing action that leaves the top edge free of breakout. They are fast cutting and are therefore ideal for grooving and trimming veneered and laminate faced surfaces.

Up/Down-cut shear flute cutters

Up/Down-cut shear flute cutters have opposing top and bottom cutting edges that prevent breakout on both the top and bottom edges, making them ideal for cutting and trimming veneer and double faced laminate boards. All sheer flute bits can be honed by hand, because the flute sides are still flat.

Spiral cutters

Spiral cutters are suitable for small mortising and pocket cutting operations on timber. Available as either up-cutting or down-cutting, their action is to either draw the shavings up out of the cut, or push them down through the workpiece. The slicing action of spirals leaves a neat clean edge that is even better than the shear cutters because they make a single continuous uninterrupted cut with each revolution.

Their disadvantage is that they are difficult to hone correctly by hand. They are also used extensively for slotting and cutting aluminium alloy extrusions in the window industries, but in these situations cutting lubricant is required to prevent the material melting and sticking to the flutes.

Stagger tooth cutters

Stagger tooth cutters are used for heavier morticing work, or when cutting deep pockets for locks and other door and joinery fittings, the extra clearance ability and rigidity of a staggered tooth cutter is helpful.

However, you still have to make several passes to get the required depth and larger sizes can make the router more difficult to hold steady due to the amount of vibration they produce.

Plastics and acrylics

Plastics and acrylics. Although standard straight, spiral and shear two flute cutters can be used for machining rigid plastic and acrylic materials, specially ground cutters are available for this purpose.

Always use a PTFE spray to prevent ‘weld back’ when routing soft plastics that are inclined to melt during cutting, applying it both behind the cut and to the cutter itself. Select a suitable cutting speed to keep the edge temperature low and minimise chattering along the edges of the cut.

Shop for Straight Router Cutters

Find our full range of router cutters here, from top brands such as Trend and CMT.

You may also be interested in other Guides to Router Cutter Types

01726 828 388

01726 828 388