✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

Price

PriceKreg Answers to Common Pocket Hole Questions

Answers to Common Pocket Hole Questions

The most frequently asked questions about pocket hole joinery.

Can you disassemble and reassemble pocket-hole joints?

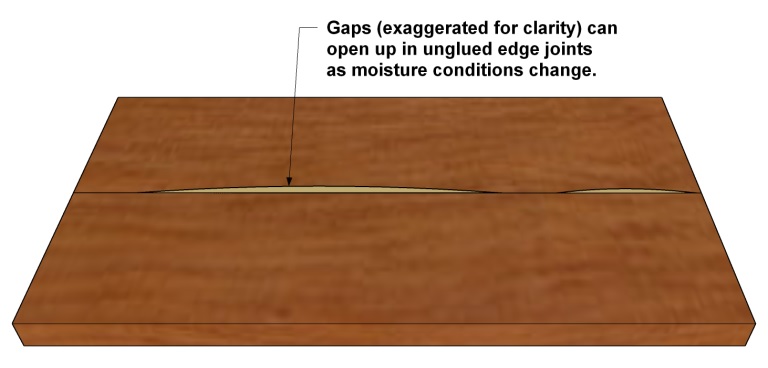

Can you assemble pocket-hole joints without glue?

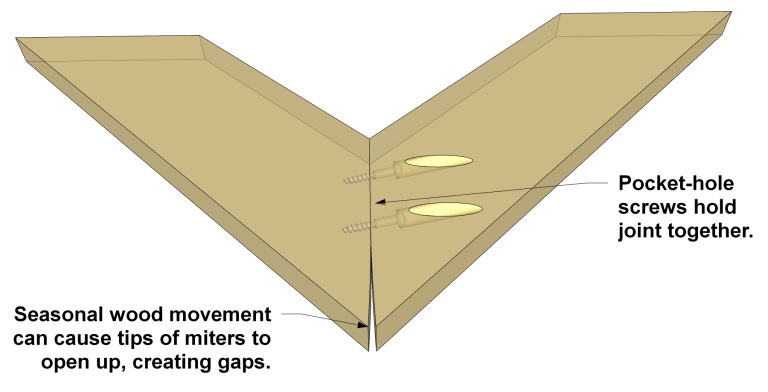

* Miter joints: Mitered corners, like you’d use when building a picture frame, can also benefit from glue. Once again, seasonal wood movement is the reason. It can cause the miter joint, especially at the tips, to open up. Adding glue to a mitered pocket-hole joint can help prevent this.

Outdoor projects: Projects that live outdoors face much harsher conditions. Humidity and temperature vary a lot more, and many projects get rained and snowed on. This all makes seasonal wood movement more extreme. Plus, water will find its way into the joints and accelerate deterioration of the wood. Using exterior wood glue in the pocket-hole joints of your outdoor projects will help seal them up, so the joints will stay tight and strong in harsh outdoor conditions.

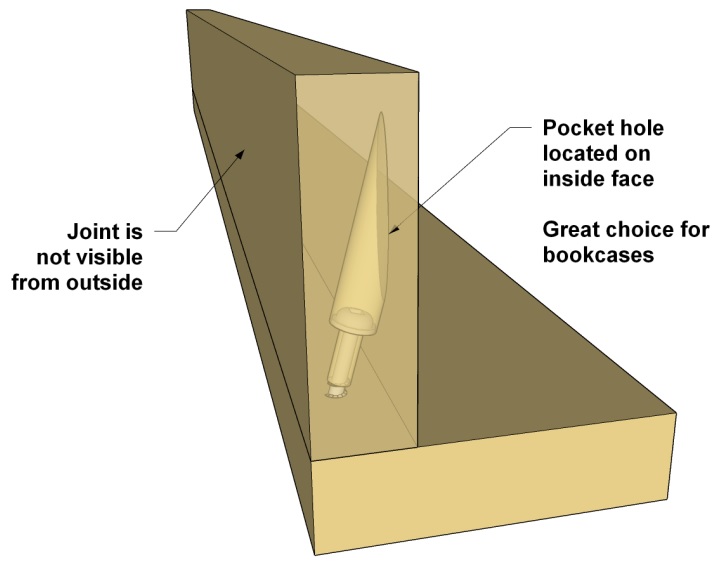

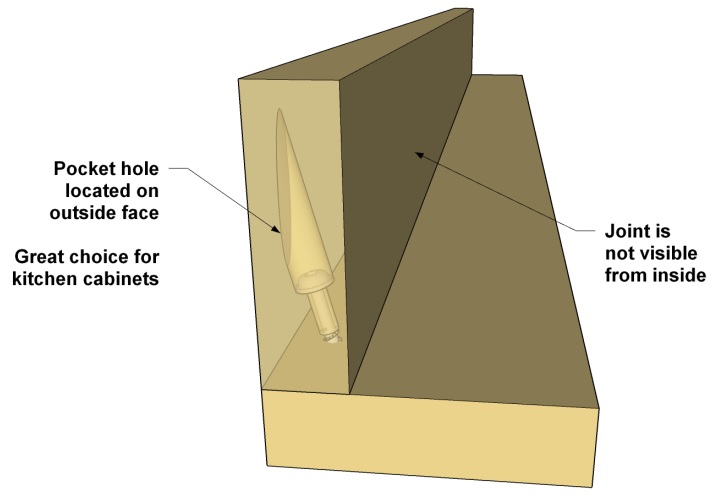

What’s better for projects - pocket holes on the inside or the outside?

* Outside for cabinets: On a kitchen cabinet, though, the outside is usually hidden by adjacent cabinets or by a cover panel. So it makes more sense to put the pocket-holes on the outside, so that you won’t see them when you open the cabinet doors.

How do you prevent over-drilling and over-driving pocket holes?

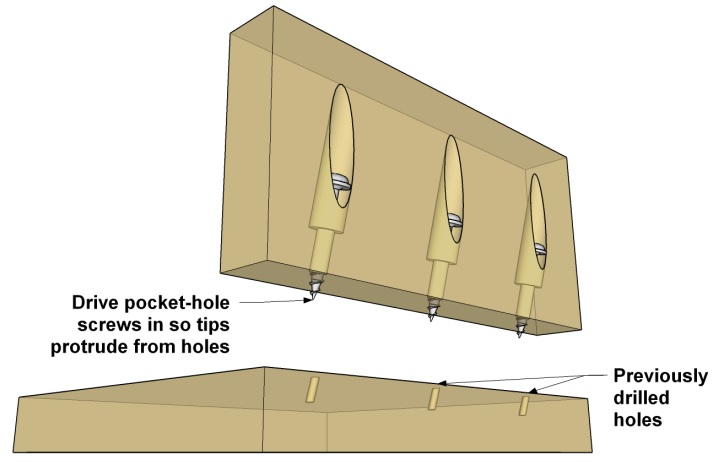

How do you prevent joints from shifting while driving screws?

How do you select the correct screw size?

Using the right kind of pocket-hole screw is critical to strong, long-lasting joints.

Find Kreg Pocket Hole Screws here

See the full range of Kreg Tools, Pocket Hole Joinery Systems and Screws

01726 828 388

01726 828 388