✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

Price

PriceQuick Guides to Routing Jigs and Templates

A Guide to Routing Jigs and Templates

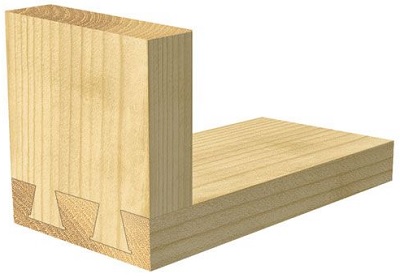

Dovetail Jig

When cut by hand, the classic dovetail joint invokes admiration from any woodworker. Unfortunately, unless you are very skilled and have plenty of time, it is a joint that is beyond the ability of most of us, particularly if there are many to cut. But with a suitable jig, not only does a dovetail joint become a reality, but the speed and quality of the finished job is outstanding and totally repeatable.

There are several jigs available depending how much control you want to have over the final appearance. At the lower end of the scale, a basic dovetail jig will cut lap, or rebated dovetails but will not allow you to vary the pin spacing. You can however change the template for smaller joints or even to cut a comb joint or for dowelling.

More elaborate jigs allow you to vary the size and layout of the pins and tails and also cut proper through dovetails, rather than being restricted to the lap joint. These may initially seem rather complicated, but in fact many of the jigs are extremely simple to set up and you can change the start point of the joint, or the thickness of the material without the need for major adjustment.

Shop for Dovetail Jig

Mortise and Tenon Jig

Mortise and tenon joints are used in many forms of joinery work such as frames for panel doors, carcasses for furniture and cabinets legs and rails for tables and chairs. Traditionally, they were cut either by hand, or by using different machines for each operation.

However, you can simplify the whole procedure using the router in conjunction with a mortise and tenon jig. On the better quality jigs, once it is set up to cut the tenon, the mortise is automatically set, which ensures a totally accurate fit each time. No repetitive marking out is needed; all you have to do is change the cutter and guide bush to switch between the two applications.

The jig is adjustable in both planes to allow angled or compound tenons to be cut, as well as the normal square ended versions. You can also use it to cut all the other forms of mortise and tenon such as haunched and mitre, as well as for drilling dowel holes.

Shop for Mortise and Tenon Jig

Staircase Jig

For those involved in building staircases, special housing jigs are available for accurately routing out the housings in the strings. As there is inevitably a lot of material to be removed, such jigs are normally used with a heavy- duty router and feature a reversible fence so each string can be matched perfectly.

Shop for Staircase Jig

Letterbox Jig

This jig can be adjusted for size and is quickly set up, with the opening remaining perfectly square at all times.

Shop for Letterbox Jig

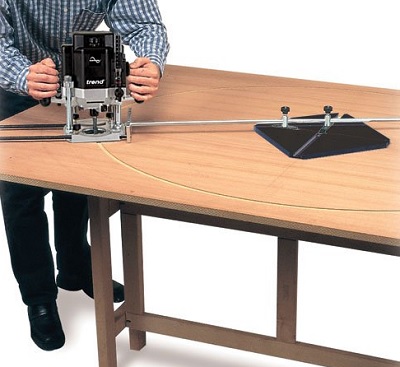

Ellipse and Circle Cutting Jig

This jig is designed to enable virtually any router to cut an accurate ellipse or circle and is ideal if you are a cabinet maker forming tabletops, arches and the like. Using a router with this jig is perhaps the only way to get the perfect circular forms necessary for high quality work.

Shop for Ellipse Jig

Worktop Jig

Shop for Worktop Jigs

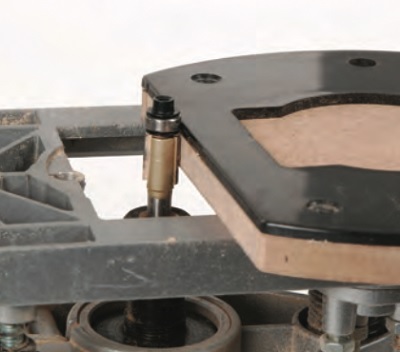

Hinge Jig

is both quick and simple and there is no need for the conventional time-consuming marking out. Obviously, the cornern of the recess is left radiused, but this is quickly squared up using a corner chisel.

You can find a fully in depth step-by-step guide to using a hinge jig here.

Shop for Hinge Jigs

Lock Jig

This jig uses a set of interchangeable templates to cut both the mortise and the faceplate recess for a variety of different sized locks. Always a difficult job to do by hand, the deep mortise is cut very cleanly even on hardwood using a suitable long reach cutter. Once again, you will need to square out the corners of the faceplate recess.

Shop for Lock Jigs

Hole Cutting Jig

It is often necessary to have access points for pipes and cables beneath wooden floors. This jig allows you to cut the 250 mm diameter openings and then place the waste piece into a spacer ring as a removable lid. Suitable for 18 mm and 22 mm thick wooden floors, the jig yet again, demonstrates the versatility of the router for a wide range of applications.

Shop for Routabout Hole Cutting Jig

Varijig Frame System

This adjustable jig allows you to make up square or rectangular frames to any dimension, which can then be used to machine recesses, slots, panel moulds etc.

Shop for Varijig Frame System

Belfast Sink Jig

An adjustable jig to accurately rout out the aperture in a solid wood kitchen worktop with the back corner radius and drip groove on the underside. For single or double Belfast or Butler sinks, it is used in conjunction with the draining board jig.

Shop for Belfast Sink Jig

Draining Board Groove Jig

This jig is specially shaped to produce grooves which are very slightly sloped to assist the water to run away.

Shop for Drainer Groove Jig

Making your own Routing Jig

It must also be quick and easy to remove and replace the workpiece accurately, so some form of datum stop and quick release clamps are required on most jigs. In some situations, it is necessary for the router to cut through into the jig itself, so allow for this by making a particular component replaceable, or by incorporating a sacrificial work pad. Most importantly, the jig must be safe, holding everything securely and allowing you to work with your hands well away from the cutter.

Jig Making Materials

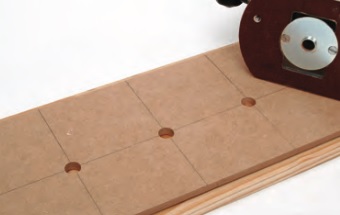

liable to move, even when seasoned properly. So its use should be restricted to smaller structural components rather than important guiding surfaces. Even small amounts of natural movement are enough to destroy the accuracy of a jig, so combining hardwood with MDF achieves the best of both worlds. Good quality plywood is another very solid jig making material though it is considerably more expensive than MDF and often not as flat.

Other plastic materials are also available, but due to their higher cost, they are best restricted to only the most critical parts of the jig. Tufnol is a superb material that is smooth and strong and can be machined with most TCT cutters. The cheaper alternative is clear acrylic sheet, which again is easily machined, but is more brittle. A good compromise is to use MDF for the majority of the jig and then cover any surfaces that are subject to wear with a layer of laminate. This is easily applied using an impact adhesive, leaving it slightly oversize and then trimming back with a suitable bearing guided cutter.

More sophisticated jigs will need removable or adjustable components, such as levers, threaded inserts, scales and template making material, as well as double sided tape and toggle clamps for holding the workpiece in the jig. Having made your jig, it is obviously important to hold the work securely within it and you may have to adopt various holding strategies. These depend on the type of work, but as well as the toggle clamps mentioned above, other alternatives include the use of spikes, eccentric cams, double-sided tape, wedges, abrasive paper, special mats and vacuum beds.

Sometimes the work has been predrilled as part of its manufacture and this hole may be used as a means of locating and securing it. In fact, any clamping method can be used, as long as it doesn’t interfere with the path of the router or restrict the removal of the work from the jig.

You will soon build up quite a collection of different jigs so it is worth labelling each one with what it does and also make a note on it if there are any particular cutters or guide bushes that are needed for its use.

Attaching the Router to a Jig

Some of the most useful jigs and work aids need to be fitted directly to the router base. When you are purchasing a router make sure it has suitable tapped holes in its base. Look for routers with the TBC logo which is a standard configuration for many bolt on sub bases and router table fixings. For future reference, when you start making jigs and templates, it is a good idea to make up a pattern of your router base.

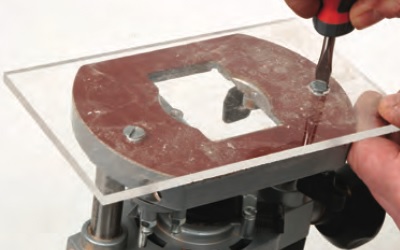

If your router has a detachable soleplate, the job of making this template is very much easier. Simply remove the soleplate and fix it with double-sided tape to a piece of thin MDF which has been roughly cut to shape. Then use a flush trimming cutter in the router, minus its soleplate, to produce a perfect pattern.

The fixing holes are easily located using the soleplate as a drilling guide. If the base is not detachable, a pattern can be made by drawing around the router base and then cutting or sanding the MDF to shape.

Alternatively, the fixing holes can be accurately located by making a couple of sharpened studs from appropriately threaded bolts, cutting off the heads and sharpening one end.

Then screw these into place in the base so that the points are just sticking out proud, then press the router down onto the template and the hole centres will be marked perfectly.

The alternative is to use the Trend Unibase that is drilled to accept most routers. If the router doesn’t have any fixing holes other than those for the guide bush, you can always the use the guide bush itself as a template to get the holes accurately located.

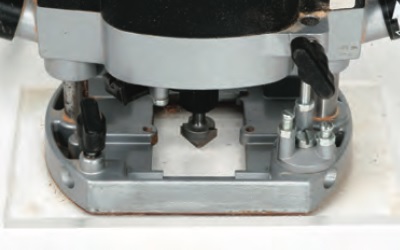

Making a Router Base Extension

Often on edge moulding jobs there is very little support left for the router, particularly if it is a narrow workpiece or you are working round a corner. In this situation, it is so easy to accidentally tilt the router and leave an unsightly scoop in the mould. Those routers with very large base openings are particularly vulnerable.

Beware of making this extension plate too thick or you will reduce the depth of the plunge capacity of the router. 6mm or 9mm material is plenty thick enough.

For larger and heavier routers, this setup may still not provide sufficient support and a larger base extension with two guide handles may be necessary.

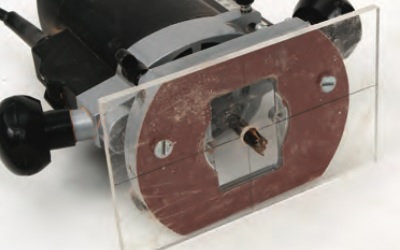

Making a Centre Finder

Then plunging down with a V cutter to mark the centre point.

Now remove the Perspex and scribe the crosshair lines at 90° to each other, with the intersection centred on this marked point.

Replace the Perspex on the router and drill through it with a cutter slightly bigger than the one you’ll be using for the drilling operation.

To use the jig, the location of each hole is marked on the workpiece with intersecting lines and the jig just needs to be lined up with these before plunging in with a suitably sized cutter.

You can even bore holes at an angle by adding shims to one end of the base though this makes precise centring more difficult. A variation on this is to locate the router onto the drilling template using a guide bush which is a close fit in the template.

Making a Trimming Jig

This simple jig is designed for quickly trimming the end of boards to exact length and leaving a perfect finish across the end grain, something not normally possible unless you have a panel cutting table saw. All you need is a perfectly straight timber batten about 250 mm long and no thicker than the material being trimmed. Stick this to a piece of MDF with another perfect straight edge, making sure that the two form a right angle. Make this MDF slightly longer than the widest piece you anticipate trimming and also make sure that the batten end is flush with the edge of the MDF.

Cut the workpiece to within about 2 mm with a saw, then clamp it to the jig or use some double-sided tape to hold it in place, lining up the end of the batten with the cut line. Now use a bearing guided trimming cutter to run across the end of the board using the edge of the MDF as the guide.

This will result in a perfectly clean and square cut in both planes and is a wonderful aid if you have a batch of boards to prepare for a project such as a bookcase.

Making a Housing Jig

The simple housing joint is one of the most useful for building shelf units and cabinets. Cutting the necessary groove with a router makes it almost foolproof, providing you can guide the cutter accurately. This jig is very similar in construction to the trimming jig but is made with a heavier section batten which extends well beyond the end of the MDF fence. Use it with a bottom cut two flute cutter, but this time use the base of the router running against the fence as the guide. You must maintain positive pressure against the fence at all times to prevent the cutter wandering off course. If you don’t have a cutter of exactly the right size, take two passes with a narrower cutter, moving the jig to the required amount.

After the first groove is cut, it is a simple matter to line up the jig for each subsequent housing by positioning the edges of the cut groove in the batten against the marked lines on the work.

If the housings are to be stopped, you can either stick or screw stop blocks onto the MDF to limit the amount of travel of the router.

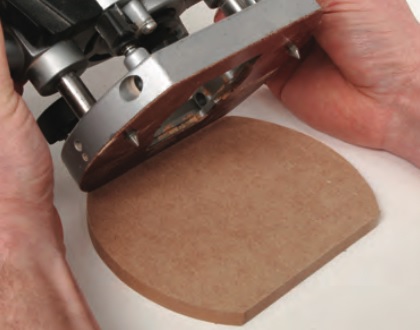

Making Routing Templates

For the professional user, this is vital as it speeds up the work flow and minimises material wastage. Each piece cut from a specific template will be identical to the next. Templates can be used with guide bushes or bearing guided cutters.

If you are using a bearing guided cutter, the template is easier to make as it is exactly the same size as the workpiece, but it doesn’t allow you to control the depth of cut, essential for work such as inlaying.

With a guide bush, the situation is a little more complicated and the template obviously has to be cut over or under size to allow for the guide bush margin, but you do have control over the depth of cut.

Also, by fitting different sized guide bushes in the router you can use just one template to cut different sizes.

Another difference between the two guiding methods shows up at external sharp corners, which become slightly radiused if you are using a guide bush.

Templates should be designed to afford as much support for the router as possible. In situations where the router overhangs the edge of a template, or the template extends beyond the edge of the workpiece, levelling blocks should be fitted to prevent the router tilting and producing a cut that doesn’t register properly with the template.

The template obviously has to be strong enough that it does not distort during use, but if you’re using a guide bush it is also important that the thickness of the template material exceeds the depth of the guide bush ring and allows a clearance of, at least 1 mm, between the tip of the ring and the surface of the workpiece.

It is essential that the template is followed in the correct direction to keep the ring tight against the guide edge. If you don’t, the cutter will deflect away. Remember to work anti-clockwise on external templates and clockwise for internal templates to maintain this correct orientation. There is a necessary compromise to be made as regards to fixing the template on the work. It needs to be perfectly secure to accurately reproduce the pattern, but you should be able to remove it easily for repositioning on the next piece. In some situations, simple locating blocks and the downward pressure of the router will hold the template in place, but it is always advisable to secure it further with cramps or some other holding device.

On painted or concealed work, the template can be simply pinned or screwed in place. Templates can be cut from any piece of smooth surfaced sheet material that is easy to work and finish. Although it must be thick enough to keep the guide bush clear of the work, it must not be so thick that it reduces the depth of cut. MDF is suitable for general use, but for templates likely to be used more often, materials such as ‘Tufnol’ or non shattering plastic are recommended. All the edges must be finished really smooth as any unevenness will be reflected on the finished cut. Ideally try and use the router itself for this shaping as it will leave the template edges smooth and square without requiring any further cleaning up.

On flat work it can be held in place with double-sided tape provided the surfaces are dust and grease-free. If you anticipate using a particular template frequently, seal the surface with sanding sealer and you’ll then get much better adhesion with double- sided tape.

Although you could theoretically use the router with a template to actually cut out a shape, realistically, this is rarely practical, you would have to use large diameter cutters to prevent them snapping and the amount of time and waste involved is prohibitive.

To reduce the time and wear on the cutter, cut the workpiece roughly to size with a bandsaw or jigsaw and then use the router in conjunction with the template to trim back the exact dimension.

The most basic template is a simple straightedge which is either clamped or stuck to the workpiece. This allows you to make a trimming cut if you use a bearing mounted cutter, or to cut grooves if you use the guide bush and a two flute cutter. For better control, particularly for grooving, or for critical cuts like worktops, the double straightedge is better, with the guide bush running within a suitable slot cut in the template.

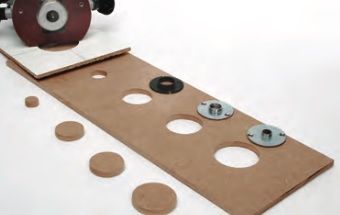

Making a Circle Template

Circular templates are also very useful to cut and trim curves to a required smooth shape. The finished result is entirely down to the quality of your templates, but you can then use the router to cut circles, round corners and ovals as well as holes and recesses.

To form a circle template first cut a smooth sided hole with a suitable hole saw. For accuracy, do this on a drill press and clamp the template material securely to make sure it doesn’t move.

From this one template, a series of decreasing diameter templates can be cut using different guide bush and cutter combinations.

To cut templates of a larger diameter use a self guiding rebate cutter. In the centre of the new template, cut the hole roughly to size with a jigsaw and then tape or pin the new template over it.

With the rebate cutter fitted in the router, set the depth of cut fractionally deeper than the template material (the cutter will cut slightly into the surface of the first template). Position the router with the bearing through the hole in the top template and cut away the waste by running the bearing around the inside edge of the bottom template.

Guide bushes can also be used with templates for locating the router when fitting dowels or support pegs for shelves etc. Mark out the centre-point of each dowel position on the template or a square edged piece of clear plastic. Drill a hole equal in diameter to the guide bush. Locate the template over the workpiece by either fitting locating blocks or by scribing lines across the guide bush hole and then holding the router securely, plunge in to drill the hole.

Ready-Made Router Templates

There is an equally large range of ready- made templates available for more common applications. The advantage of manufactured templates is that they are usually of better quality than those you can make yourself and the finish produced from the cutter is therefore better. Others allow you to use the router for more artistic purposes such as inlay or panelling work. For sign work there are dedicated templates for cutting numbers and letters that only require the use of a small guide bush and a suitable cutter.

Other useful bought templates are available for fitting cable tidies in desktops and for repairing damaged areas of timber.

We offer a Wide Range of Routing Templates and Jigs

01726 828 388

01726 828 388