✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

Price

PriceTormek Guide to Grinding Wheels

Tormek Guide to Grinding Wheels

Which grinding wheel should you choose?

Before deciding which grinding wheel you should get, start by looking at your needs and your sharpening. Will you sharpen different types of tools with different angles? Do you want several characteristics in the same single grinding wheel? Are you looking for the smoothest surface finish? It's your needs that decide.

Here you can compare qualities and characteristics between grinding wheels to help you find the right grinding wheel for you.

Original Grindstone

The Original Grindstone is the perfect all-round grindstone. The grit can be adjusted between 220 and 1000 grit with the SP-650 Stone Grader. This makes it excellent for both coarse and fine sharpening, and it easily sharpens most types of tools and steel grades.

- All-round grindstone with adjustable sharpening characteristics equivalent to between 220 and 1000 grit.

- Long service life, often lasts many years.

- Can be trued with the TT-50 Truing Tool to regain a perfectly flat surface.

- Can grind most steel grades.

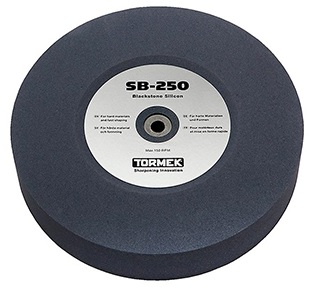

Blackstone Silicon

The combination of grit hardness, shape and size makes the Blackstone Silicon work efficiently at the low rpm speeds of the Tormek machine. The higher abrasiveness of the stone is especially valuable when shaping tools with a large bevel or sharpening surface where the grinding pressure is low, such as planer blades and woodturning chisels. The Blackstone Silicon has sharpening properties equivalent to 220 grit. The SP-650 Stone Grader allows the surface of the stone to be adjusted up to an equivalent of 1000 grit. Its sharp and relatively small grits mean it sharpens efficiently even at low sharpening pressure. This means that the Blackstone Silicon holds its shape exceptionally well over time and thus has a very long service life.

- More efficient sharpening of HSS and other high-alloy steels.

- Adjustable sharpening characteristics equivalent to between 220 and 1000 grit.

- Effective even at lower grinding pressure.

Japanese Waterstone

- Provides a mirror-finish polished bevel.

- 4000 grit.

- Provides superior sharpness.

Diamond Wheel Coarse

- Fast steel removal to repair or reshape edges.

- Constant shape, always maintains the same diameter.

- Sharpens all types of steel and ceramic.

- Allows sharpening on the flat side of the grinding wheel for a completely flat bevel.

- Exceptional durability with diamond, the world's hardest abrasive.

Diamond Wheel Fine

This diamond grinding wheel can sharpen all types of materials, including steel, ceramics and carbide. The grinding wheel has a grit of 600, providing fast sharpening and a smooth surface finish. The constant shape makes it possible to sharpen either on the side of the wheel or on its upper surface. Side sharpening is perfect for smaller tools such as knives, chisels, carving gouges and v-tools. The result is an edge with a completely flat bevel, instead of a slightly concave surface.

- Effective steel removal combined with a smooth finish.

- Constant shape, always maintains the same diameter.

- Sharpens all types of steel and ceramic.

- Allows sharpening on the flat side of the grinding wheel for a completely flat bevel.

- Exceptional durability with diamond, the world's hardest abrasive.

Diamond Wheel Extra Fine

With this diamond grinding wheel, you can sharpen all types of materials, including steel, ceramics and carbide. The Diamond Wheel Extra Fine is a diamond grinding wheel that provides an extra smooth finish and is especially suited to carving tools and knives requiring minimal steel removal. It is 1,200 grit. The Diamond Wheel Extra Fine is especially appreciated by woodcarvers and others who need a mirror finish on the bevel. If you need to give your tool a new edge or shape, it's best to do that on another grinding wheel first and then use your Diamond Wheel Extra Fine to give the final finish. The constant shape makes it possible to sharpen either on the side of the wheel or on its upper surface. Side sharpening is perfect for smaller tools such as knives, chisels, carving gouges and v-tools. The result is an edge with a completely flat bevel, instead of a slightly concave surface.

- Provides an extra smooth finish.

- Constant shape, always maintains the same diameter.

- Sharpens all types of steel and ceramic.

- Allows sharpening on the flat side of the grinding wheel for a completely flat bevel.

- Exceptional durability with diamond, the world's hardest abrasive.

Explanation of Terminology

Material Removal

Determines how efficient a grinding wheel is at removing material from the tool being sharpened. A higher degree of material removal means that the grinding wheel is more efficient at removing material, and so repairing or reshaping an edge will go faster.

Polishing / Finish

Determines how finely polished the sharpened surface gets from the grinding wheel. A higher score in the Polishing / Finish category means that the grinding wheel provides a higher degree of polished finish on the tool after sharpening, and less "scratch marks" are left from sharpening. A high score in this category category is desirable on tools for fine woodcarving, or other applications where you require an extremely smooth cut. Or if you want a mirror finish for an enhanced visual appearance.

Tool Steel

Determines how well suited the grinding wheel is for sharpening common tool steels, often used in hand tools. A higher score in this category means that the grinding wheel is better suited for sharpening common tool steels.

HSS / Hard Metals

Determines how efficient the grinding wheel is at sharpening HSS, exotic alloy steels, tungsten carbides or other hard metals, often used in wood turning tools and specialized knives. A higher score in this category means that the grinding wheel provides a more efficient sharpening of such hard metals.

Can Sharpen Ceramic (Y/N)

Defines if the grinding wheel is able to sharpen ceramic or not, like ceramic knives for example. Since ceramics generally are such hard and brittle materials, only certain abrasives can sharpen it.

01726 828 388

01726 828 388