✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

Price

PriceTormek Guide to Sharpening Drill Bits

Tormek Guide to Drill Bit Sharpening

Always Sharp Drill Bits

GIVE NEW LIFE TO YOUR DRILL BITS

With the patented DBS-22 Drill Bit Sharpening Attachment you can sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill size and material. You can completely restore worn drills as well as broken drills to a perfect shape.

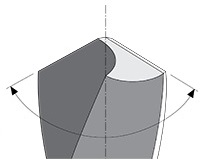

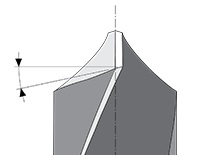

Drill Point Geometry

Drill bits usually have a point angle of 118° or 130°. There are also 120°, 135°, 140° and 150° point angles. Hard steel and stainless steel require larger point angles. Also long-chipping material, such as copper and aluminium is best drilled with a larger point angle. When drilling plexiglass, the risk of cracks when the drill goes through the material is reduced with a smaller point angle, about 90°. Centering drills usually have a 90° point angle.

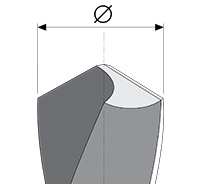

A drill bit needs to have the right lip clearance angle to cut the material. The clearance angle varies from 7° to 14°. A drill with a larger clearance angle cuts more easily, but if the angle is too large, vibrations will occur and the drill will cut irregularly and quickly become dull. If the clearance angle is too small, the drill will not cut at all, but will become hot and rapidly destroyed.

The optimal clearance angle for the job depends on the material – a harder material requires a drill with a smaller clearance angle while a softer material can have a larger angle. The size of the drill is also a determinant for the selection of the optimal clearance angle. A larger drill should have a smaller clearance angle while a smaller should have a larger one.

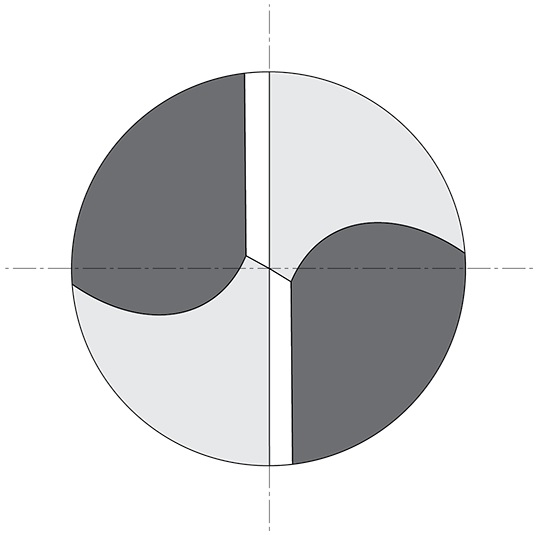

Many new drill bits are ground with a basic cone point. The two cutting lips meet in the centre and form a chisel edge, C. This point geometry is not ideal, since the chisel edge needs to be pressed into the material without cutting. The friction of the chisel edge creates much heat, which decreases the life of the drill bit. Since the chisel edge has no tip, the drill walks when drilling a new hole, which is not pre-drilled.

More expensive drill bits are ground with special points of various types. These drills must be re-sharpened in their original production machines or in special machines, which are available only at a few specialist sharpening shops. They can also be re-shaped to a 4-facet point with the Tormek attachment.

A BETTER CUTTING GEOMETRY

When you sharpen your drill bits with the DBS-22 Drill Bit Sharpening Attachment, you create a four-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drills. A four-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill.

A precision sharpened four-facet point generates less heat and the life of the drill is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit.

Sharpens all point angles:

It can be set at any angle between 90° and 150°.

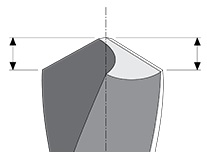

Sharpens drill bits from 3–22 mm:

One and the same drill holder copes with all sizes between 3 mm (1/8") and 22 mm (7/8"). No change of chuck required.

Always equal cutting edges:

The two cutting edges are sharpened symmetrically and work in perfect unison which prolongs the life of the drill.

Always the right clearance angle:

The optimal clearance angle can be set according to each drilling requirement to 7°, 9°, 11° or 14°.

The Four-Facet Point

Choose the Right Point Angle

Choose the Right Clearance Angle

The choice of clearance angle is crucial to the cutting performance and duration of the drill. The optimal clearance angle depends both on the drill diameter and the material to be drilled. A harder material requires a drill with a smaller clearance angle while a softer material can have a larger angle. Standard drills have a clearance angle of 11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

See the full range of Tormek Sharpening Systems, Jigs and Grinding Wheels

01726 828 388

01726 828 388