✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

Reset Filter

Price

PriceTormek Guide to Sharpening Woodcarving Tools

Tormek Guide to Sharpening Woodcarving Tools

Sharp Tools - Cleaner Cuts

SHARPEN DELICATE TOOLS WITH HIGHEST PRECISION

* Woodcarving tools are often quite delicate - most time just honing is enough. Never use a dry grinding bench grinder or belt grinder!

* Generally use less sharpening pressure on tools with arched edges since they have a smaller contact area with the grinding wheel.

* Make sure you have good lighting, you must clearly be able see the "line of light".

* Honing is extremely important to get nice, clean cuts.

Technique for Sharpening Carving Gouges and V-Tools

The technique for sharpening carving gouges and V-tools differ from tools such as plane irons and wood chisels with a straight edge – the steel is thinner and the edge angle smaller, which makes them more delicate to sharpen. Often honing can be enough to touch up the edge.

Since a carving tool often has an arched edge the sharpening takes place on a narrow and convex spot and the surface that is in contact with the grindstone is very small. This means that the grinding pressure can become very high, even if you apply only a small amount of pressure on the tool with your hands.

If you would sharpen more than necessary on a flat bevel, e.g. on a plane iron, it does not matter. But if you over sharpen on a spot on a curved edge, the shape of the edge will be changed and needs to be re-ground. This is also the case for V-tools – over grinding on one wing means that the entire edge must be re-ground.

First ask yourself whether you need to sharpen your tool or if you should only hone it. This applies especially when working with small and delicate tools with a small edge angle. A slight over-grinding on a spot on these tools makes a pronounced pit or hollow on the contour of the edge.

The basic recommendation is therefore not to sharpen small and delicate tools, but to hone them on the leather honing wheel with PA-70 Honing Compound. Sharpening on a grinding wheel is however required in the following cases:

* The edge has become too dull to be honed.

* You want to change the shape of the edge, e.g. the edge plane angle.

* You want to change the edge angle.

* The edge has become damaged.

The Sharpening Process

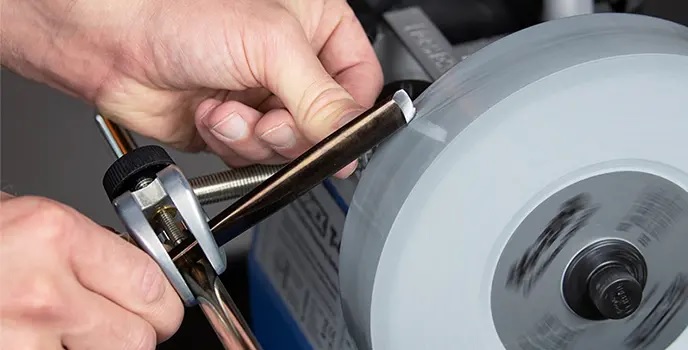

Sharpening can be done either free hand or with jigs on the grindstone. Using jigs is easier and gives you a better result as you can concentrate on where the edge touches the grinding wheel without needing to pay attention to the edge angle and the positioning of the tool, which is controlled by the jig. Before you start sharpening, grind the edge to its correct shape. Viewed from the side, the edge should look like a straight line, the edge plane angle.

Good lighting is important for all sharpening and honing work, but it is an absolute necessity when sharpening carving gouges and V-tools, since you must clearly be able see the line of light. Use a flexible lamp and position it close to the machine.

Carving gouges and V-tools have wings. These lean more or less forward when the bevel lies flat on the wood. The inclination can be described as the edge plane angle. This angle controls how the tool will cut in the wood. It should be around 20° to make the wings and the centre part of the edge work in the best way and leave a clean cut in the wood. This recommendation is independent of the edge angle.

NOTE: Grinding woodcarving tools on high speed grinders and belt grinders is absolutely not recommended! They grind too aggressively, which makes it impossible to control the grinding and the heat development draws the hardening of the thin steel.

Honing Woodcarving Tools

After sharpening, the bevel is honed to give it as fine a surface as possible. The remaining burr on the flute (inside) must also be honed away. The outside honing can be done free hand with a fine grit bench stone or with jigs on your honing wheel. The inside can be honed freehand with slip stones or on your LA-120 Profiled Leather Honing Wheel.

Honing is very important, as a finer surface on the bevel and flute makes the tool cut more easily and also makes the sharpness last longer. The surface left on the wood will also be smoother with a perfectly honed tool.

It is an advantage to use the jigs also when honing. By doing so, you work at exactly the same angle as when sharpening and the edge receives exactly the same movement pattern towards the honing wheel as towards the grinding wheel. Furthermore, you can make test cuts in the wood and then – if necessary – go back and continue the honing, with exactly the same position of the tool towards the honing wheel.

Rounding of the Tip

The Tormek leather honing wheels work in the same way as a strop made of leather glued onto a piece of wood. If you look at the edge under a microscope, you will notice that the very outer tip of the edge is slightly rounded off as the leather honing wheel is not as firm as a grindstone. However, when using a jig this rounding off is negligible and has no negative influence on the cutting ability of the tool. Actually it is likely that the microscopic rounding off reinforces the very outer sensitive tip of the edge.

Theoretically, an edge tip honed on a flat hard bench stone could be considered to be sharper. However, this is only the case before you start to work with the tool. As soon as the edge penetrates into the wood, it will be affected by the fibres and become microscopically rounded off and even bent. This is because the outer tip is extremely sensitive on these tools, which have small edge angles, sometimes only 20°. What determines the practical quality of the edge sharpness and its durability, is how the tool works after a couple of cuts in the wood.

No items in this category

01726 828 388

01726 828 388